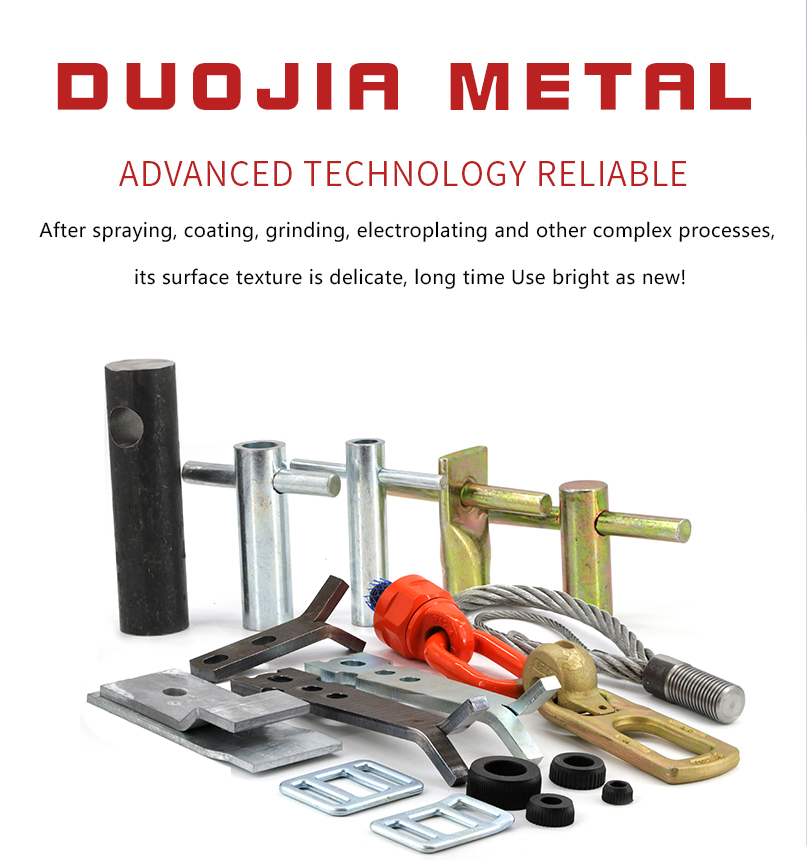

✔️ Izinto eziphathekayo: Intsimbi yeCarbon

✔️ Umphezulu: Akukho nto

✔️Intloko: Umjikelo

✔️IBakala:4.8

Ukwazisa ngemveliso:

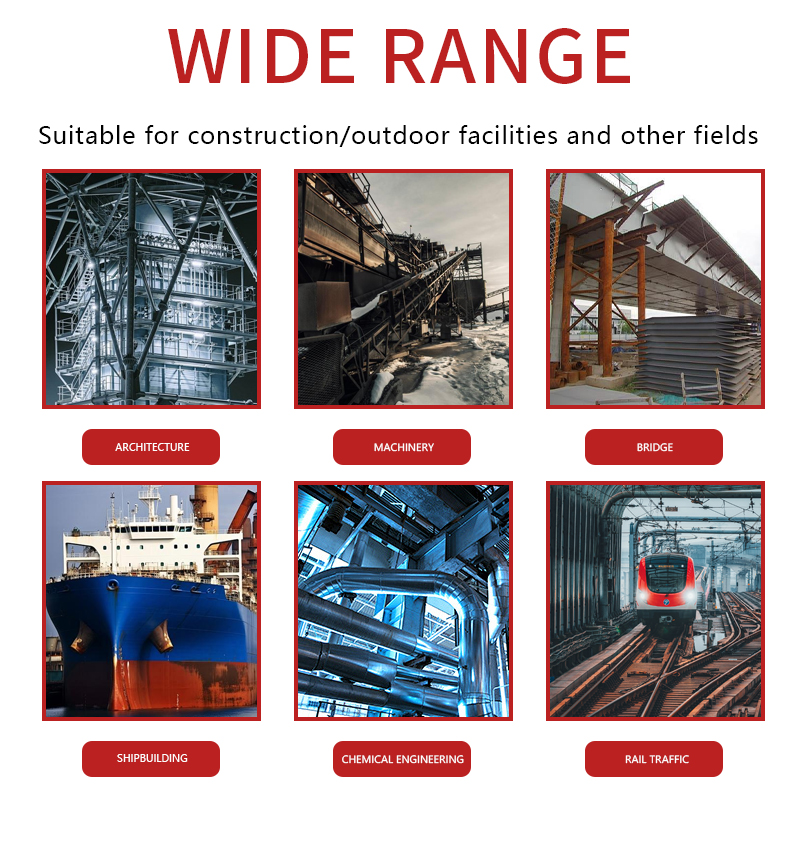

Izincedisi zekhonkrithi ze-precast zizinto ezibalulekileyo kushishino lwekhonkrithi ye-precast. Zisetyenziselwa ukunyusa ukusebenza, ukuzinza, kunye nokudityaniswa kwezinto zekhonkrithi zangaphambili. Ezi zincedisi ziqhele ukwenziwa kwizinto ezifana nentsimbi, iplastiki, okanye ialloys zentsimbi, ezikhethwe ngamandla azo, ukuqina, kunye nokuhambelana nekhonkrithi.

Iindidi eziqhelekileyo ziquka:

- Ukuphakamisa iiankile: Njengee-ankile ezisasazwayo, ezisetyenziselwa ukuphakamisa ii-slabs zekhonkrithi zangaphambili. Kufuneka zisetyenziswe kunye neentambo zeringi. Xa uphakamisa i-slab yekhonkrithi ngokuthe tye, inokufakwa kwiimbombo ezine ze-slab okanye kwiikona ezintathu ze-triangle edibeneyo ehambelana neziko. Ukuphakamisa ngokuthe nkqo, banokubekwa kumacala omabini. Ezi iankile zihlala zinento yokhuseleko edlula amaxesha ama-3 kwaye zihlala ziza nezatifikethi ezifanelekileyo njenge-CE.

- Connection Insert: Lungiselela unxibelelwano phakathi kwamacandelo ahlukeneyo ekhonkrithi okanye phakathi kwezinto ze-precast kunye nezinye iindawo zesakhiwo. Baqinisekisa ukudibanisa okukhuselekileyo kunye nokuzinza, okwenza ukuba ukuhanjiswa kwemithwalo.

- Iinkxaso ze-Rebar kunye ne-Spapers: Njengezitulo ze-rebar kunye namavili e-spacer, ezi zincedisi zigcina indawo echanekileyo kunye nesithuba semivalo yokuqinisa (ii-rebar) ngaphakathi kwekhonkrithi engaphambili. Oku kubalulekile ekuqinisekiseni imfezeko yesakhiwo sekhonkrithi, njengoko inceda ii-rebars ngokufanelekileyo ukuqinisa ikhonkrithi kunye nokuxhathisa amandla okuqina.

- Formliners: Isetyenziselwa ukwenza ulwakhiwo oluthile, iipateni, okanye ukugqibezela kumphezulu wezinto zekhonkrithi zangaphambili. Zingaphucula umtsalane wobuhle bemveliso yokugqibela, kwaye zikwaluncedo kwizicelo apho kufuneka ukubamba umphezulu othile okanye inkangeleko.

- Iinkxaso zeBar kunye neRustication Strips: Ibha ixhasa ukubamba ii-rebars kwindawo ngexesha lokugalelwa kwekhonkrithi, ngelixa i-rustication strips isetyenziselwa ukwenza iigrooves ezihombisayo okanye ezisebenzayo kunye neepateni kumphezulu wekhonkrithi engaphambili.

Imiyalelo yokusebenzisa

- Ukhetho:

- Ukuqwalaselwa komthwalo: Misela iimfuno zomthwalo wesakhiwo sekhonkrithi ekhonkrithi. Umzekelo, ukuba sisicelo esinzima sokuphakamisa umsebenzi, khetha ukuphakamisa iiankile ezinomlinganiselo ofanelekileyo womthwalo osebenzayo. Jonga kwiinkcukacha zomenzi womthwalo - ulwazi lomgangatho.

- Ukuhambelana: Qinisekisa ukuba izincedisi ziyahambelana nemathiriyeli yekhonkrithi yangaphambili kunye nawo nawaphi na amanye amacandelo abaya kusebenzisana nawo. Ngokomzekelo, izinto zokufakela ukudibanisa kufuneka zidibanise kakuhle kunye nekhonkrithi kwaye zingabangela nayiphi na imichiza enokuthi idibanise idibeneyo.

- Imiba yokusingqongileyo: Qwalasela iimeko zokusingqongileyo apho ielementi yekhonkrithi yeprecast iya kusetyenziswa. Kwiindawo ezidliwayo, khetha izixhobo ezinomhlwa - iingubo ezixhathisayo okanye ezenziwe ngokugqwala - izinto ezixhathisayo njengensimbi engenasici.

- Ukuhlohla:

- Isikhundla esifanelekileyo: Ukuphakamisa iiankile, zifake kwiindawo ezichanekileyo ngokweemfuno zoyilo. Ukubekwa ngendlela engafanelekanga kunokukhokelela ekulayisheni okungalinganiyo kunye nokusilela okunokwenzeka ngexesha lemisebenzi yokuphakamisa. Sebenzisa iitemplates okanye izixhobo zokumakisha ukuze uqinisekise indawo echanekileyo.

- I-Attachment ekhuselekileyo: Xa ufaka ukudibanisa ukudibanisa, qinisekisa ukuba zifakwe ngokuqinileyo kwikhonkrithi ye-precast. Oku kunokuquka ukusebenzisa izinto zokuncamathelisa ezifanelekileyo, iziqhoboshi zoomatshini, okanye iindlela ezifanelekileyo zokuphosa ukuqinisekisa ukuba izinto ezifakelweyo zibotshelelwe ngokufanelekileyo kwaye zinokudlulisela imithwalo ngokufanelekileyo.

- YeRebar-Izincedisi eziNxulumeneyo: Isikhundla se-rebar inkxaso kunye ne-spacers ngokuchanekileyo ukugcina isigqubuthelo esichanekileyo kunye nesithuba se-rebar. Oku kuhlala kubaluleke kakhulu ukuhlangabezana neemfuno zekhowudi yokwakha kunye nokuqinisekisa ukusebenza kolwakhiwo lwento ye-precast.

- Ukuhlola kunye noLondolozo:

- Uhlolo lokuhlohla kwangaphambili: Ngaphambi kofakelo, jonga ngononophelo izincedisi kuzo naziphi na iimpawu zomonakalo, njengokuqhekeka, ukonakala, okanye ukubola. Yala naziphi na izinto ezineziphene.

- Iitshekhi rhoqo: Hlola rhoqo izincedisi ezifakelweyo ngexesha nasemva kwenkqubo yokwakha. Khangela iimpawu zokuguga, ukukhulula, okanye umonakalo. Ngokomzekelo, khangela ukuphakamisa ii-ankile kuzo naziphi na iimpawu zokukhathala okanye ukuguqulwa emva kokusetyenziswa ngokuphindaphindiweyo.

- Iintshukumo zoLondolozo: Ukuba kukho nayiphi na imiba efunyenweyo, thatha amanyathelo okulungisa afanelekileyo. Oku kunokubandakanya ukuqiniswa kwezibophelelo, ukutshintshwa kwamalungu adlekileyo, okanye ukufaka izaleko ezongezelelweyo zokhuselo njengoko kufuneka.

-

zombini icala weld iliso iinkuni isikrufu

-

Umgangatho ophezulu we-Metal Frame Anchor

-

Ifektri zobonelelo iziqhoboshi carbon steel antiskid-...

-

Phakamisa Isakhiwo seCarbon Steel Zinc Plated Bolt Anchor

-

Intsimbi engatyiwayo yeHex Socket Cup Ibhonti yentloko DIN912...

-

Ivenkile ethengisa impahla DIN 6923 Flange Nut – Black Zinc/Oxid...